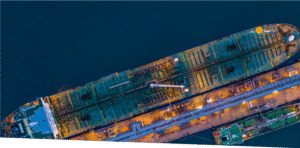

DNV offers guidance on the matter of corrosion in ballast water & cargo tanks, highlighting that the actual corrosion rate may differ, with factors like temperature and coating condition playing significant roles in the deterioration process.

According to DNV, the actual corrosion rate in ballast and cargo tanks may differ from the assumptions in the rules and the embedded corrosion models. DNV survey data reveals a significant rise in corrosion findings in water ballast and cargo tanks in oil tankers and bulk carriers at the third renewal survey, with a peak at the fourth renewal. That means that for some vessels, the useful life of the effective coating protection may only be about two-thirds of the requirement of the Performance Standard for Protective Coatings (PSPC). Continue reading “Corrosion in ballast water & cargo tanks”

The Norwegian Government has decided to introduce zero-emission requirements in the World Heritage fjords. In a circular the Norwegian Maritime Authority (

The Norwegian Government has decided to introduce zero-emission requirements in the World Heritage fjords. In a circular the Norwegian Maritime Authority ( The

The

Lloyd’s Register (LR) has issued an update to its Retrofit Research Programme, with the latest report focusing on the developments in Engine retrofits for alternative fuels.

Lloyd’s Register (LR) has issued an update to its Retrofit Research Programme, with the latest report focusing on the developments in Engine retrofits for alternative fuels. The International Marine Contractors Association (

The International Marine Contractors Association ( Recently published, a new report produced by the Canal & River Trust aims to show how vital the UK’s waterway network can be as the Government tries to tackle climate change. The 30-page Climate Adaptation Report spells out how important canals and waterways are and how they can be part of action against problems such as storms, flooding and drought, which have badly affected areas of the UK.

Recently published, a new report produced by the Canal & River Trust aims to show how vital the UK’s waterway network can be as the Government tries to tackle climate change. The 30-page Climate Adaptation Report spells out how important canals and waterways are and how they can be part of action against problems such as storms, flooding and drought, which have badly affected areas of the UK. New analysis by the Maritime Emissions Reduction Centre (MERC) has found that silicone-based hull coatings could deliver significant emissions reductions, but challenges around application and mechanical strength remain.

New analysis by the Maritime Emissions Reduction Centre (MERC) has found that silicone-based hull coatings could deliver significant emissions reductions, but challenges around application and mechanical strength remain.

Ten oil spills of more than seven tonnes were recorded from tanker incidents in 2024, the same number as in 2023 according to ITOPF oil tanker spill statistics.

Ten oil spills of more than seven tonnes were recorded from tanker incidents in 2024, the same number as in 2023 according to ITOPF oil tanker spill statistics.